A semi-trailer is a type of trailer where the front axle is absent. A significant proportion of its weight is carried by a road tractor, a front axle assembly which is detachable and termed a dolly, or even the tail belonging to another trailer.

A semi-trailer usually comes with a landing gear which supports it when uncoupled. Legs of the landing gear can be lowered for support.

A semi-trailer truck is a road tractor attached to a semi-trailer. It is also known as a semi or eighteen wheeler truck in the US. Typically, the fifth wheel of the truck connects to a semi-trailer Kingpin.

GAWR and GVWR

Each semi-trailer carries weight that is within the weight ratings limit displayed on the its identification/certification plate. There are two valid ratings: GAWR and GVWR

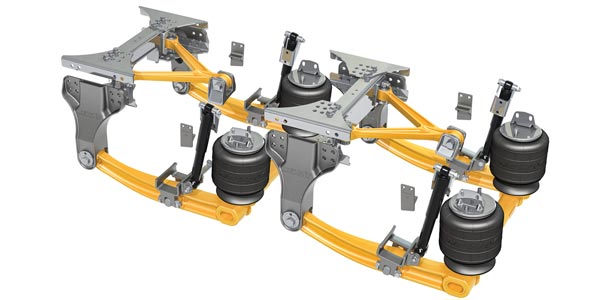

GAWR: The Gross Axle Weight Rating is defined as the structural capability of the lowest rated component of all running gear components, hub, wheels and drums, suspension and spring system, tires, axles, brakes, rims and bearings.

GVWR: The Gross Vehicle Weight Rating is defined as the structural capability of the eighteen wheeler when it is supported by the axles and the kingpin and when the load is distributed uniformly across the cargo space.

The semi-trailer will carry a load that is equal to the GVWR, less the eighteen wheeler weight. Any cargo loaded should be properly clamped down, braced and blocked so that shifting of loads does not occur. Further,it is also required to comply with local trucking laws.

Semi-Trailer maintenance

A semi-trailer should be properly maintained in order to obtain the performance it is built for.

Electrical system: All lights and reflectors should be cleaned. It should be ensured that all lights function properly. Broken reflectors and lights that are burned out should be promptly replaced. Wiring should not be frayed and must be correctly protected. Fuses should not be replaced by metal foils. It is advisable to use parts built by the manufacturer.

Brakes: They should be maintained properly. Eighteen wheeler brakes will function as long as they are not abused. Maladjusted brakes are the principal reason for a lengthier stopping distance. The brake life will be shortened if not maintained. It is better to connect with the manufacturer's preventive maintenance service for an optimal load carrying experience.

Tires: They should not be over-inflated. Tires should be verified for correct inflation when they are cold. They should also be inspected for nail, stones and other foreign objects stuck in the rubber or between duals. It is to be ensured that the dual tires situated on any of the axle ends must have the same diameter. The total load on each tire should not exceed the figure specified by the manufacturer of the tire.

Correct usage of hand-holds and steps: Extreme caution must be adopted when using hand-holds and steps. They are subject to environmental as well as user damage. Ensure that components are maintained properly. They should be firmly attached to the body of the truck.

Safety defects

The semi-trailer manufacturer should be contacted immediately if a safety defect is found. You can also contact the relevant local administering authority. Defective trailers can prove to extremely hazardous on the road. Checking for safety defects must be treated as a priority exercise.

Contact the semi-trucks, heavy equipment specialists at ITAG Trucks & Equipment for more information on drop deck trailer or dump trucks

Article Source: http://EzineArticles.com/expert/Chris_CH_Green/1712514

by Chris CH GreenArticle Source: http://EzineArticles.com/8067341